Re-allocation

Re-allocation occurs after the Picklist is created.

While re-allocating, the system searches for the most efficient way for that moment and takes into account if inventory should be allocate from a standard bin or bulk locations. This means that the initial allocation can only be seen as a stock reservation.

Bulk picks vs Fine picks

What separates Bulk Pickers (Reach Trucks) and Fine Pickers (walking pickers).

Fine picking is only applicable in the case the product has a standard bin (configurable under the Warehousing tab in product maintenance). If there is sufficient inventory on a standard bin, a fine picker will pick the inventory. In all other cases, we speak of bulk picking.

When bulk picking/replenishment is involved there are a number of rules that apply in sequence:

- Pallets that are on PICKING bins but NOT on the standard BINs (standard bins are used by fine pickers).

- Opened pallets at BULK locations.

- FIFO on BULK locations.

- If FIFO equals -> smallest QTY.

Bulk Pickers pick directly or replenish from a bin locations whose purpose is bulk or picking.

Below is a table that indicates which picking strategy is recommended based on the reallocation of inventory.

| product configuration | order qty | qty avbl on PICKING bin | qty avbl on BULK bins |

|---|---|---|---|

| Items DO have a standard bin | 30 | 1 x 100 | 1 x 90 |

| 1 x 100 | 1 x 80 | ||

| 1 x 100 | |||

| 1 x 70 | |||

| 1 x 70 |

| product | bin | purpose | container | qty | open/close | expires | fifo |

|---|---|---|---|---|---|---|---|

| DEMO_PRODUCT | 123 456 0 (standard) | picking | 0 | ||||

| DEMO_PRODUCT | 123 456 1 | picking | #CNTNR1 | 100 | closed | later | 1st |

| DEMO_PRODUCT | 123 456 1 | picking | #CNTNR2 | 100 | open | later | 1st |

| DEMO_PRODUCT | 123 456 1 | picking | #CNTNR3 | 70 | open | later | 1st |

| DEMO_PRODUCT | 123 456 1 | picking | #CNTNR4 | 70 | open | sooner | 1st |

| DEMO_PRODUCT | 123 456 3 | bulk | #CNTNR5 | 90 | open | later | 1st |

| DEMO_PRODUCT | 123 456 1 | picking | #CNTNR6 | 100 | closed | later | 2nd |

| DEMO_PRODUCT | 123 456 3 | bulk | #CNTNR7 | 80 | open | later | 2nd |

Picking strategy

Based on the two tables above the following picking strategy is suggested.

- Because no inventory is available on a standard bin (used by fine pickers) this scenario becomes a BULK pick/replenish scenario.

- Closed containers will not be given priority.

2.1 Filtered container #CNTNR2, #CNTNR3, #CNTNR4, #CNTNR5 and #CNTNR7. - Eventhough, open container #CNTNR7 has less inventory it is received later.

3.1 Filtered container #CNTNR2, #CNTNR3, #CNTNR4 and #CNTNR5 - FIFO equals to containers #CNTNR2, #CNTNR3, #CNTNR4 and #CNTNR5, select the smallest quantity.

4.1 Filtered container #CNTNR3 and #CNTNR4.

4.2 Container #CNTNR3 expires later.

4.3 Filtered container #CNTNR4

Replenish the opened container #CNTNR4 with an earlier received_on date containing the smallest quantity and expires the soonest.

Picklist states

The diagram below shows what statuses a picklist line can have, inventory items will follow that state.

Pending –> picklist is created, assigned or replenished.

Pending or Skipped –> first pick is done for a picklist-line.

Completed –> last pick is done for a picklist-line it will go to completed.

Skipped –> picklist line is skipped.

Replenish –> no inventory in the bin-location according to the re-allocation rules.

Cancelled –> picklist line is cancelled.

stateDiagram-v2

[*] --> Pending

Pending --> Replenish: replenish

Replenish --> Pending: replenished

Replenish --> Cancelled: cancel

Pending --> Picking: pick

Pending --> Skipped: skip

Pending --> Cancelled: cancel

Skipped --> Picking: pick

Skipped --> Cancelled: cancel

Picking --> Completed: complete

Picking --> Cancelled: cancel

Completed --> [*]

Cancelled --> [*]

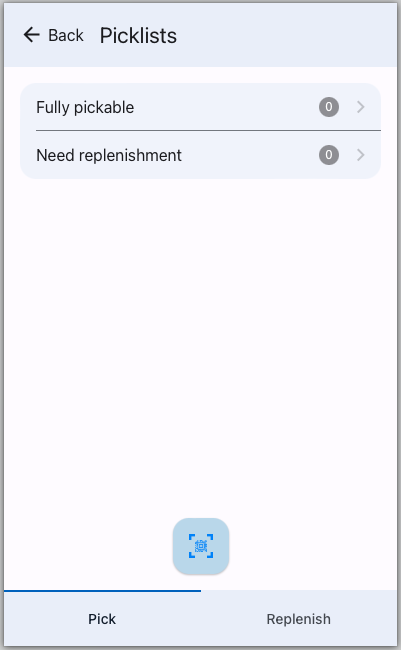

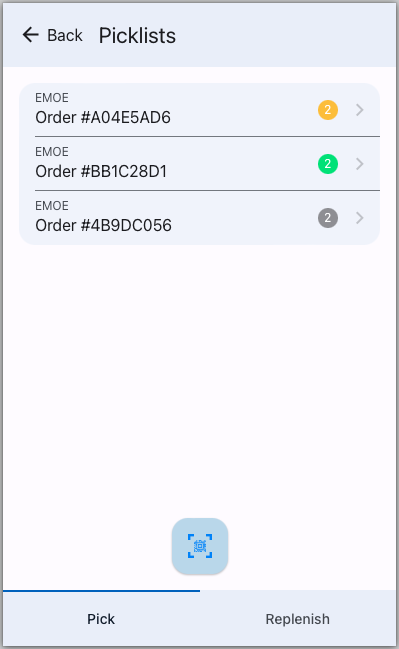

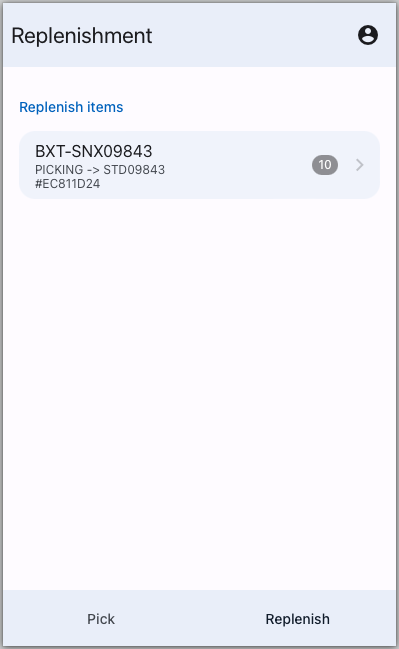

Roles

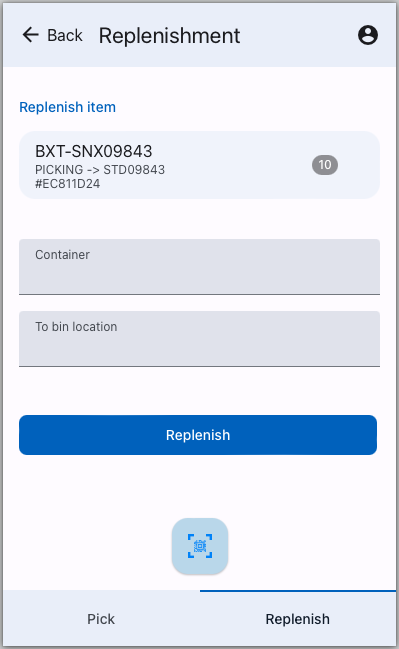

It is not allowed for a picker to replenish stock. It is not allowed for a replenisher to pick stock. For this reason, the Pick and Replenish views - at the bottom of the screen - will not be displayed, but will be displayed if the roles are combined.

Roles Picker/Replenisher combined

Pick and Replenish views displayed.

Fully pickable

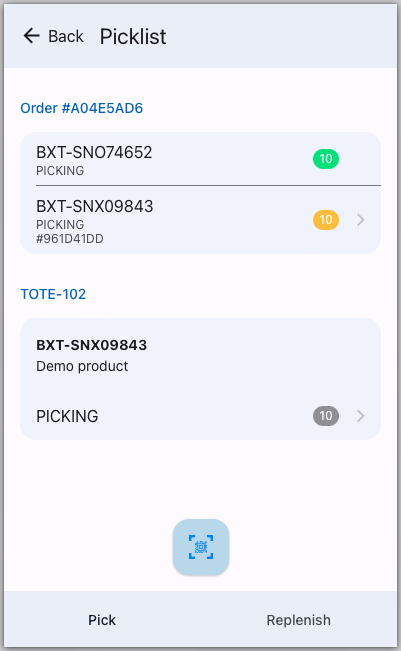

Picklist order details

- Container(s) of allocated inventory are displayed. If not scanned, a popup will appear with the option to scan another container or proceed.

- If a picklist line is partially picked and skipped as shown above, the picklist will display it as partially skipped in the picklist overview as shown below.

- No container is displayed for picklist lines that are completely picked (or picking loose inventory items).

Picklist in different states

Yellow -> (partially) skipped.

Green -> partially picked (waiting for replenishment).

Grey -> Pending

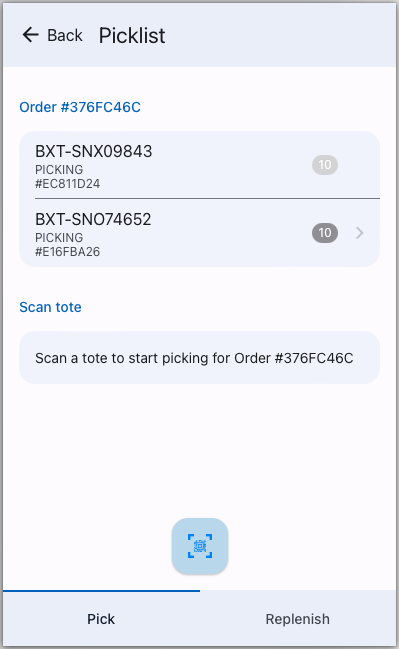

Need replenishment

A standard binlocation must be replenished if the order quantity is more than what is available.

It is allowed to replenish inventory to a non-standard bin. It is not allowed to replenish inventory to a standard bin for another product. This means that it is not possible to configure multiple bin locations for the same product.

To be able to replenish and indicate to the pickers if a product on the picklist should be replenished we give the picklist-line a state - replenish. However, if no picklist can be generated because inventory cannot be allocated, visit the report Inventory On Non Standard Binlocations.

Picklist in need of replenishment

Only the 2nd picklist line could be picked, the first requires to be replenished.

Replenishment overview

Inventory allocated to a picklist to be replenished.

Replenish inventory

Replenish to standard binlocation or a different binlocation that is not a standard binlocation.